Smart Integrated Production Line for Meat Products Series

This equipment is crafted from SUS304 stainless steel, featuring a sleek exterior, robust structural integrity, stable material conveyance, and safe operation. It utilizes a SUS304 stainless steel filter plate for efficient preliminary material screening, with a slag-collecting tray positioned beneath the vibrating surface.

The machine itself is constructed by bending SUS304 plates (3.0 mm thick) and finished with a matte-textured surface treatment. Its supporting frame is reinforced through multi-point linear welding, ensuring exceptional structural stability.

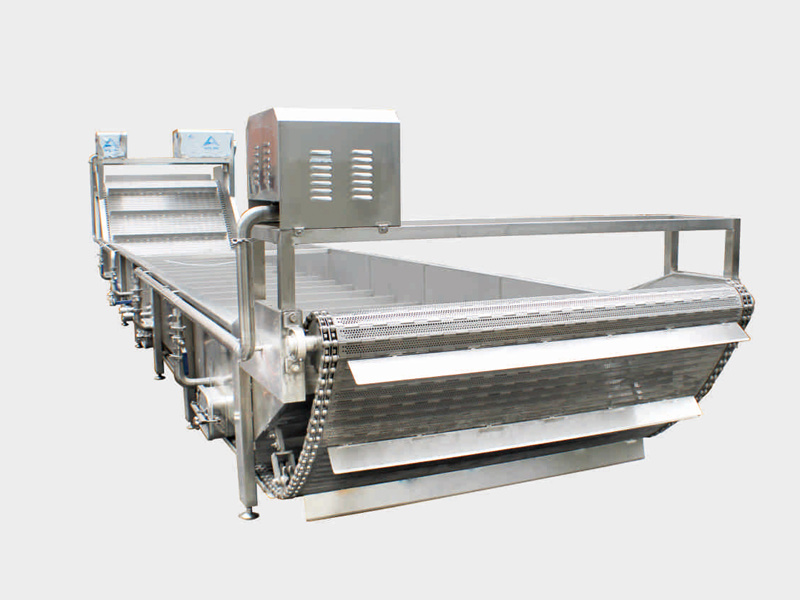

The thawing machine is entirely made of stainless steel. This equipment is an automated thawing system custom-designed to meet specific customer needs and tailored to the characteristics of the materials being processed. Typically, it uses ambient-temperature water with bubbling action for gentle thawing. In colder winter conditions, steam-assisted heating can be employed to achieve rapid thawing results.

The machine features variable-frequency speed control, ensuring stable conveyor speeds and enabling seamless, continuous production—plus, its operation can be adjusted at any time. The conveyor mesh is crafted from high-strength, premium-grade stainless steel, offering a robust structure capable of handling heavy loads. This innovative design not only revolutionizes traditional thawing methods but also significantly boosts thawing efficiency, while keeping operation simple and user-friendly.

This equipment is ideal for the automated thawing of frozen meat products, including items like chicken feet, chicken legs, pork (with skin), beef, rabbit meat, duck meat, or other frozen meat products.

Bubble Washing and Cooling Machine

The entire machine of the bubble washing and cooling system is made from stainless steel and consists of components such as a tank body, a conveyor system, and a spray mechanism. It employs advanced bubble-based tumbling wash technology combined with spray irrigation to thoroughly remove impurities from the materials. At the bottom, a row of perforated air ducts generates bubbles under high-pressure air pump operation, causing the materials to tumble continuously in water for efficient cleaning. This ensures that every surface of the product is fully exposed to the cleaning action, effectively eliminating dirt, mud, salt residues, and other contaminants—leaving the materials clean, hygienic, and free of any hidden死角. Additionally, the discharge end is equipped with multiple spray nozzles for a second round of rinsing, guaranteeing a comprehensive and spotless clean. The conveyor system can be fully lifted out of the washing tank, making it easy to clean and maintain.