This equipment is crafted from SUS304 stainless steel, featuring a sleek exterior, robust structural integrity, stable material conveyance, and safe operation. It utilizes a SUS304 stainless steel filter plate for efficient preliminary material screening, with a slag-collecting tray positioned beneath the vibrating surface.

The machine itself is constructed by bending SUS304 plates (3.0 mm thick) and finished with a matte-textured surface treatment. Its supporting frame is reinforced through multi-point linear welding, ensuring exceptional structural stability.

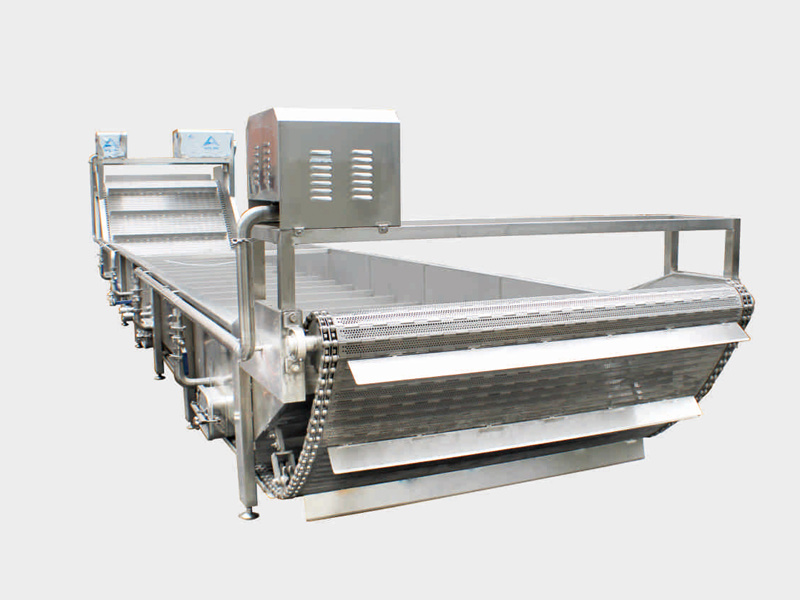

The thawing machine is entirely made of stainless steel. This equipment is an automated thawing system custom-designed to meet specific customer needs and tailored to the characteristics of the materials being processed. Typically, it uses ambient-temperature water with bubbling action for gentle thawing. In colder winter conditions, steam-assisted heating can be employed to achieve rapid thawing results.

The machine features variable-frequency speed control, ensuring stable conveyor speeds and enabling seamless, continuous production—plus, its operation can be adjusted at any time. The conveyor mesh is crafted from high-strength, premium-grade stainless steel, offering a robust structure capable of handling heavy loads. This innovative design not only revolutionizes traditional thawing methods but also significantly boosts thawing efficiency, while keeping operation simple and user-friendly.

This equipment is ideal for the automated thawing of frozen meat products, including items like chicken feet, chicken legs, pork (with skin), beef, rabbit meat, duck meat, or other frozen meat products.

Bubble Washing and Cooling Machine

The entire machine of the bubble washing and cooling system is made from stainless steel and consists of components such as a tank body, a conveyor system, and a spray mechanism. It employs advanced bubble-based tumbling wash technology combined with spray irrigation to thoroughly remove impurities from the materials. At the bottom, a row of perforated air ducts generates bubbles under high-pressure air pump operation, causing the materials to tumble continuously in water for efficient cleaning. This ensures that every surface of the product is fully exposed to the cleaning action, effectively eliminating dirt, mud, salt residues, and other contaminants—leaving the materials clean, hygienic, and free of any hidden死角. Additionally, the discharge end is equipped with multiple spray nozzles for a second round of rinsing, guaranteeing a comprehensive and spotless clean. The conveyor system can be fully lifted out of the washing tank, making it easy to clean and maintain.

Multi-stage Bubble Washing Machine

Hair-removal and pest-cleaning machine, crafted with a stainless steel mesh chain and featuring nylon brushes inside the chamber to effectively remove hair. The machine is equipped with a pest-removal roller at the discharge end, along with an integrated debris collection bin, while the bottom incorporates bubbling technology for thorough cleaning.

Application scope: Ideal for cleaning and removing hair, pests, and debris from a variety of root vegetables like carrots, potatoes, and peppers, as well as citrus fruits and other similar produce.

This equipment is designed for cleaning products such as pickled mustard tubers, ginger, fruits, and more by removing mud, debris, and peels. The upper part of the device features spray nozzles that provide all-around rinsing, while the interior is equipped with a movable filter screen to collect and easily remove cleaned-off impurities. Additionally, the equipment includes an automatic water-refilling function, and its conveyor speed can be smoothly adjusted via frequency conversion.

Multi-functional Vegetable Cutter

The vegetable slicer features a compact design, operates quietly, and delivers high efficiency at low speeds—producing around 800 kg per hour. It boasts a long service life and meets strict food hygiene standards. The process begins with centrifugal slicing, followed by conveyor transport to large blades that cut the vegetables into strips. These strips are then fed into a precision blade assembly for uniform cubing, completing the entire operation in one seamless step. The machine is capable of processing various food items, such as long strips and block-shaped vegetables, ensuring consistent thickness, evenly shaped strands with exceptional length, and excellent glossiness. Additionally, the resulting cubes and pieces maintain sharp, well-defined edges, while the unit itself is easy to maintain and repair.

This product features advanced manufacturing technology, with a pot body crafted from premium-grade stainless steel that boasts excellent thermal conductivity. This ensures even heating of the oil and allows for rapid temperature increases during the cooking process. A dedicated hot-oil pump automatically circulates the oil within the pot to the designated location, reducing labor requirements and eliminating safety risks associated with manual handling—thereby guaranteeing precise control over all product specifications.

The burner design is both highly efficient and environmentally friendly, enabling faster heating of ingredients while preserving the authentic flavor of the final product. Additionally, the appliance can be powered by multiple gas sources, including liquefied petroleum gas (LPG), natural gas, and piped city gas, offering versatile and reliable operation.

Fully Automatic Energy-Saving Wok

The equipment is primarily made of stainless steel, meeting food hygiene standards, and features a sleek, elegant design that ensures convenient operation. It’s a tilting-type, fully automatic, energy-efficient gas-powered stirring wok equipped with a tilting pot body for easy emptying of ingredients. The heating system utilizes a silent, energy-saving burner, offering safe, efficient, and highly energy-efficient performance—delivering over 30% energy savings compared to conventional gas systems. Material discharge is automated via a hydraulic system, while variable-frequency, stepless stirring speed control is integrated, along with a PLC-based control system for safe and stable operation. Additionally, the entire unit can be fitted with an automatic oil-supply system. The stirring motor boasts stepless frequency conversion, allowing seamless speed adjustments across a wide range to precisely meet food-processing requirements.

Application: Used for washing ginger

Performance Features: All materials in contact with the product are made of stainless steel, ensuring compliance with food hygiene standards.

Energy-efficient, hygienic, reduces labor costs, and minimizes manual workload intensity.

New-style Ginger and Garlic Crusher

Usage: Designed for crushing ginger and garlic

Performance Features: All components in contact with the material are made of stainless steel, ensuring compliance with food hygiene standards.

Energy-efficient, hygienic, reduces labor costs, and minimizes manual workload intensity.